VIBRATING CONVEYORS AND -TABLES, CHAIN TABLES

Vibrating tables

The vibrating table is designed to work together with vibrating and belt conveyors. It is also designed to store large quantities of material to be chipped or crushed. For example, material that is intended to be loaded with a front-end loader or forklift. The vibrating table has a large loading area, so e.g. the leveling box can be emptied directly onto the table. The conveyor includes a vibrating table that is connected to the load-bearing frame with spring elements. The conveyor works with an electric motor, which, together with an eccentric mechanism, enables vibrating movement. The low power consumption of the vibrating table is a direct result of the state-of-the-art design.

Depending on local conditions, the conveyor can be installed on a separate mounting platform.

The material is dosed from the vibrating table to the vibrating or belt conveyor. The dosing feature of the vibrating table allows the material to be continuously fed to the chipper. Our products include vibrating tables with dimensions of 2 x 3 m, 3 x 3 m, 4 x 3 m. Motor power from 5.5 KW to 11 KW.

Vibrating tables are manufactured in cooperation with Teknamotor.

Chain tables

The chain table is designed to work together with a vibrating or belt conveyor. It is also designed to store large amounts of material. From the chain table, the material is dosed onto a vibrating or belt conveyor. The synchronization of the chain table and the vibrating or belt conveyor enables a continuous feed to the chipper or crusher.

Our products include chain tables with dimensions of 2.2 x 4 m and 3 x 3 m. Motor power 1.1 KW.

Chain tables are manufactured in cooperation with Teknamotor.

Vibrating conveyors

The vibrating conveyor is the perfect solution when the material to be fed is a short and asymmetrical piece of wood, such as, for example, log pieces, scrap, saw edge boards and slats.

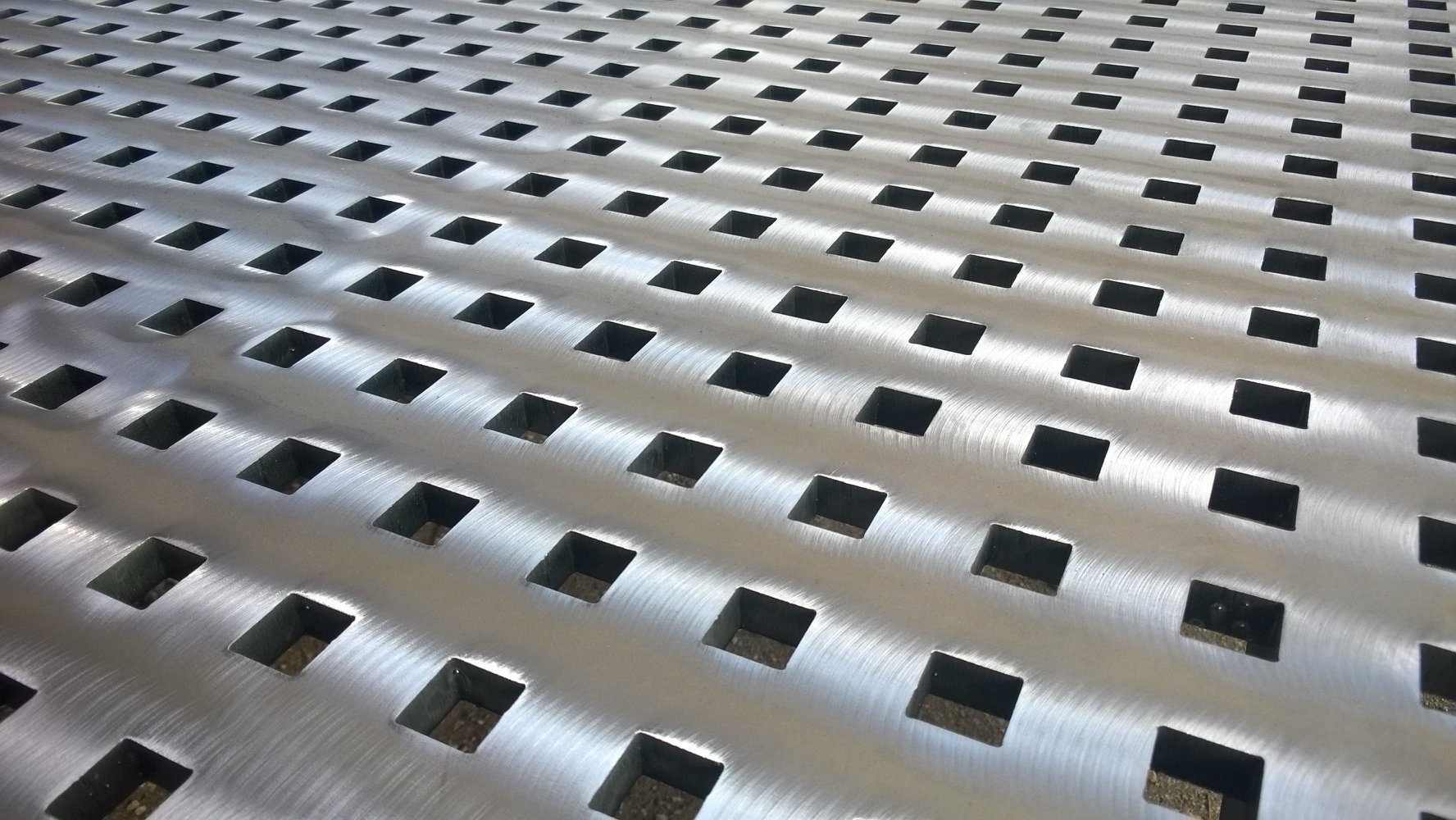

The conveyor includes a transport chute, which is connected to the load-bearing frame with spring elements. The conveyor works with an electric motor, which together with the eccentric mechanism enables vibrating movement. The state-of-the-art design enables low power consumption of the vibrating conveyor. Depending on the installation conditions, the conveyor can be installed on a separate support platform. The advantage of the vibrating conveyor is that it spreads the material evenly in the conveyor chute, so the feed flow of the material fed to the chipper or crusher is uniform.

Vibrating conveyors can also be equipped with a metal detector.

Vibrating conveyors are manufactured in cooperation with Teknamotor.